In-Mold Decorations: Integrating Layout and Manufacturing Excellence

In-Mold Decorations: Integrating Layout and Manufacturing Excellence

Blog Article

Grasping In-Mold Decorations: Strategies, Fads, and Finest Practices for Optimum Results

In the world of manufacturing, the art of in-mold designs stands as an essential aspect of item layout and production. As sectors constantly look for ingenious means to enhance aesthetic allure and performance, understanding the intricacies of in-mold decors has arised as an important capability. From choosing the right products to incorporating innovative design patterns, the trip in the direction of attaining optimal lead to this domain name is multifaceted. By delving into the strategies, trends, and finest practices that underpin successful in-mold design procedures, businesses can unlock a realm of opportunities that not just boost the aesthetic allure of their products yet also improve manufacturing performance and strengthen customer engagement.

Material Selection

Product choice is an essential element of mastering in-mold designs, as it straight affects the quality and sturdiness of the end product. When selecting materials for in-mold designs, it is vital to take into consideration aspects such as compatibility with the molding procedure, the desired visual outcome, and the environmental problems the product will certainly face. Thermoplastic materials like polypropylene, polycarbonate, and abs are commonly utilized for in-mold decorations due to their versatility and capability to achieve complex styles. These materials use exceptional moldability, allowing manufacturers to produce complicated forms and patterns with precision.

Furthermore, products with high warmth resistance are favored for in-mold decorations, particularly for items that will certainly be subjected to elevated temperature levels throughout their lifecycle. By very carefully picking the proper material for in-mold decors, suppliers can boost the overall high quality and toughness of their products, satisfying the expectations of both customers and end-users - In-Mold Decorations.

Design Technology

A necessary consider progressing the field of in-mold designs is the constant exploration and implementation of design advancement methods. Layout technology plays a critical function in boosting the aesthetic appeal, performance, and total high quality of items manufactured using in-mold decor procedures. By incorporating cutting-edge design components, makers can separate their products in the market, attract consumers, and remain in advance of competitors.

One of the essential elements of layout advancement in in-mold designs is the combination of detailed patterns, appearances, and graphics that were previously challenging to accomplish with standard design approaches. Advanced innovations such as 3D printing and digital layout tools enable designers to create complex and thorough styles that can be flawlessly transferred onto molded components. In addition, the use of vibrant shades, metallic coatings, and special results like gloss or matte structures can better boost the visual charm of in-mold embellished items.

Moreover, style technology expands beyond appearances to incorporate functional enhancements such as ergonomic shapes, integrated attributes, and adjustable elements that accommodate details customer requirements. By accepting style advancement, manufacturers can unlock brand-new possibilities for personalization, creative thinking, and item differentiation in the competitive landscape of in-mold designs.

Production Effectiveness

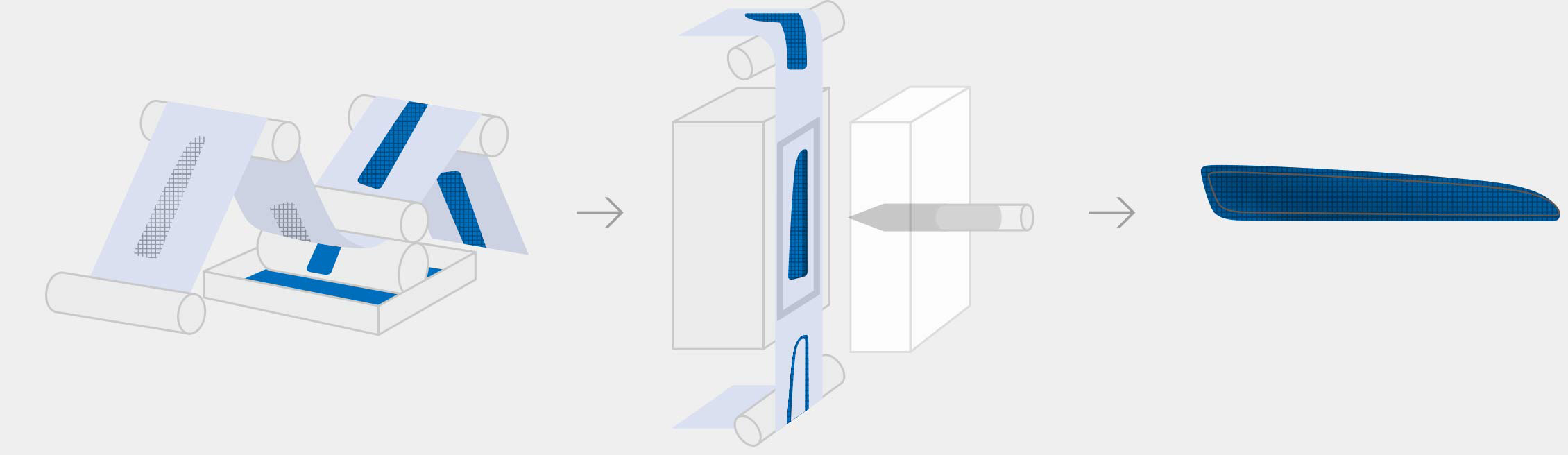

Effective production procedures are essential for translating the ingenious designs developed in the area of in-mold decors into premium ended up items that meet market demands and customer assumptions. In the world of in-mold decorations, production performance encompasses different key elements that add to the total success of the manufacturing process.

Automation not only increases the manufacturing procedure yet likewise boosts precision and repeatability, leading to a much more uniform and top notch end product. On the whole, an all natural strategy to manufacturing performance is vital in making best use of the potential of in-mold decoration techniques and achieving optimum results in the affordable market landscape.

Quality Assurance Measures

What are the key strategies for making sure rigid quality assurance measures in the world of in-mold decors? Quality assurance measures are critical in in-mold decoration processes to guarantee the manufacturing of perfect and premium ended up items. One critical method is the execution of extensive inspection methods at every phase of the production process. This involves carrying out detailed visual assessments, dimensional checks, and color consistency analyses to determine any kind of disparities or defects beforehand. a fantastic read

Using advanced innovations such as view automatic inspection systems can likewise boost the quality control procedure by giving precise and reliable information for analysis. These systems can spot blemishes that may be missed by manual evaluations, therefore improving overall product quality and consistency.

Normal training and growth programs for workers included in the in-mold decor procedure can also add to maintaining premium criteria. By educating staff on best methods, quality assumptions, and the importance of interest to information, companies can cultivate a culture of top quality awareness throughout the organization.

Consumer Charm

To improve the marketability of in-mold decor products, understanding and providing to customer choices play an important function in identifying their allure and success. Providing customization choices such as personalized styles, shade variants, and textural components can significantly boost the appeal of in-mold decor items.

Conclusion

In-mold decorations offer a reliable and versatile way to improve product aesthetic appeals. Mastering in-mold decorations needs an alternative approach that thinks about all facets of the manufacturing process to make sure success.

In the realm of production, the art of in-mold decorations stands as an essential element of item layout and production. Design advancement plays a crucial role in boosting the visual appeal, capability, and overall high quality of items produced using in-mold decoration processes.One of the vital aspects of layout advancement in in-mold decors is the assimilation of intricate patterns, structures, and graphics that were formerly challenging to accomplish with typical decoration methods.Reliable production processes are necessary for converting the innovative styles created in the field of in-mold decorations right into premium ended up products that meet market needs and consumer assumptions. Using customization options such as individualized layouts, shade variants, and textural aspects can substantially boost the charm of in-mold decor products.

Report this page